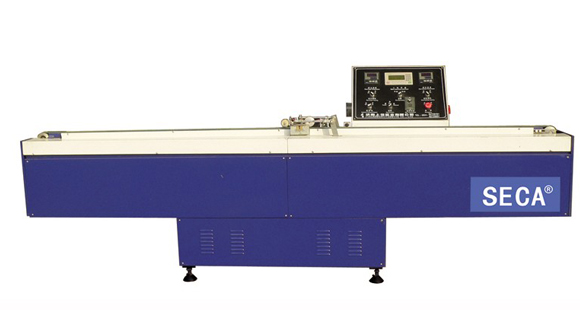

Features

1.It is the necessary machine in the process of making insulating glass.it is used for coating two sides of alum spacer.

2.Adopts man-machine interface screen,PLC control,can finish location,transmission and coat automatically.

3.Adjustable location device to make sure the space between coating head and alum frame.

4.Equipped with belt groove to adjust the space between the belt and rubber outlet

5.Adopts single touch system,can coat arc alum spacer.

6.Airhydraulic device

7.Automatic alarm device

8.Timing on-off device to save preset time

Technique paramete

1.Voltage:380V/220V 50HZ

2.Oil pump power:1.1KW

3.Heating power:3.55KW

4.Adjustable space of alum spacer:4-30mm

5.Extrude pressure:16-19Mpa

7.Transmission speed:35m/s